Yu (Jessica) Wang

Scientists are keen to develop new materials for lightweight, flexible and affordable wearable electronics, so that one day dropping our smartphones doesn't cause irreparable damage. A team from the University of California, Merced, has made conductive polymer films that actually become stiffer in response to impact rather than disintegrating, just as mixing cornstarch and water in the right amounts produces a slurry that is fluid when stirred slowly but hardens when punched (i.e., “oobleck”). ). They described their work in a talk at this week's meeting of the American Chemical Society in New Orleans.

“Polymer-based electronics are very promising,” said De Wu, a postdoctoral researcher in materials science at UCLA. “We want to make polymer electronics lighter, cheaper and smarter. [With our] System, [the polymers] It can become stiffer and stronger when you make a sudden movement, but it is flexible when you make your daily routine movement. They are neither constantly rigid nor constantly flexible. They only respond to your body movement.”

As mentioned earlier, making oobleck is simple and easy. Mix one part water with two parts cornstarch, add a little food coloring for fun, and you've got Oobleck, which behaves as either a liquid or a solid, depending on the amount of pressure applied. Stir it slowly and steadily while it is liquid. Hit it hard and it will become more solid under your fist. It is a classic example of non-Newtonian fluids.

in Perfect liquidViscosity depends largely on temperature and pressure: water will continue to flow regardless of other forces acting on it, such as stirring or mixing. In non-Newtonian fluids, viscosity changes in response to an applied pressure or shear force, thus crossing the boundaries between fluid and solid behavior. Moving a cup of water produces a shearing force, and the water shears move out of the way. The viscosity remains unchanged. But for non-Newtonian fluids such as opaque, the viscosity changes when shear force is applied.

Ketchup, for example, is a shear-thick non-Newtonian fluid, which is one reason why hitting the bottom of the bottle doesn't make the ketchup come out any faster; Applying force increases the viscosity. Yogurt, broth, slush, and pudding are other examples. And so is Oobleck. (The name comes from Dr. Seuss's 1949 children's book, Bartholomew and Oobleck.) In contrast, non-drip paint exhibits a “shear thinning” effect, can be brushed off easily but becomes more viscous once applied to the wall. Last year, scientists at the Massachusetts Institute of Technology He confirmed that Friction between particles was crucial in the transition from liquid to solid, determining the turning point when friction reaches a certain level and viscosity suddenly increases.

Wu works in the lab of materials scientist Yu (Jessica) Wang, who decided to try to mimic the shear-thickening behavior of oobleck in a polymer material. Flexible polymer electronics are typically made by linking conjugated conductive polymers, which are long and thin, like spaghetti. But these materials will still break down in response to particularly large and/or rapid impacts.

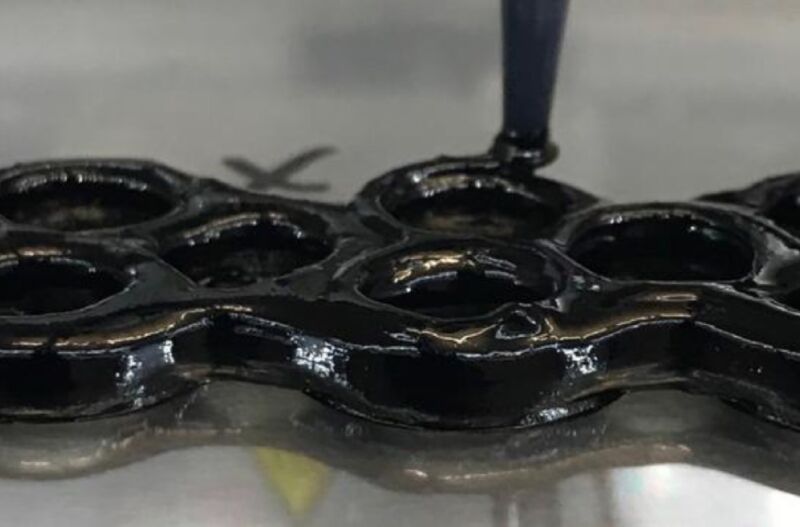

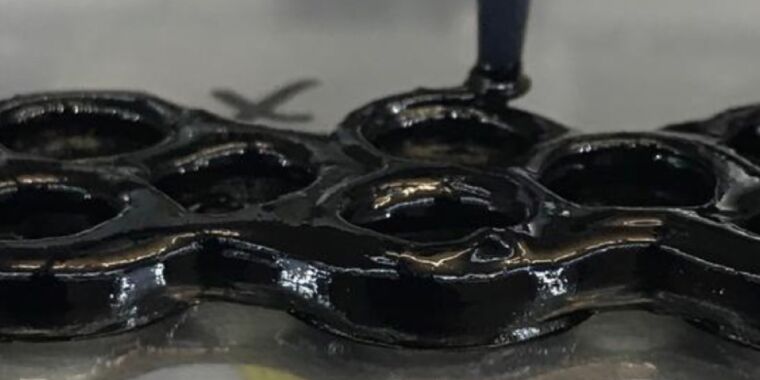

So Wu and Wang decided to combine the spaghetti-like polymers with shorter polyaniline molecules and polystyrene sulfonate poly(3,4-ethylenedioxythiophene), or PEDOT:PSS, four different polymers in all. Two of the four have a positive charge, and two have a negative charge. They used this mixture to make stretchable films and then tested the mechanical properties.

The films behave a lot like oobleck, deforming and stretching in response to impact rather than disintegrating. Wang likened the structure to a large bowl of spaghetti and meatballs, because the positively charged molecules do not like water, and thus assemble into microscopic, ball-like structures. She and Wu suggest that these microstructures absorb the energy of the collision and flatten without disintegrating. It doesn't take much PEDOT:PSS to get this effect: just 10 percent was enough.

Additional experiments identified a more effective additive: positively charged 1,3-propandiamine nanoparticles. These particles can weaken the polymer “meatball” interactions enough that they can deform further in response to impacts, while strengthening the interactions between the long, cross-linked, spaghetti-like polymers.

The next step is to apply their polymer films to wearable electronics such as smart watch bands and sensors, as well as flexible electronics for health monitoring. Wang's lab has also experimented with a new version of the material that would be compatible with 3D printing, opening up more opportunities. “There are a number of potential applications, and we are excited to see where this unconventional new property takes us.” Wang said.

“Typical beer advocate. Future teen idol. Unapologetic tv practitioner. Music trailblazer.”

More Stories

Boeing May Not Be Able to Operate Starliner Before Space Station Is Destroyed

How did black holes get so big and so fast? The answer lies in the darkness

UNC student to become youngest woman to cross space on Blue Origin